Our Hydro Pressure Testing Pump is engineered for precise and reliable pressure testing in a variety of industrial applications. Designed to meet the demanding needs of pressure testing pipelines, pressure vessels, and other critical systems, this pump ensures accurate results and dependable performance. Its robust construction and high-efficiency operation make it an essential tool for quality assurance and safety checks.

Product Details

Product Details

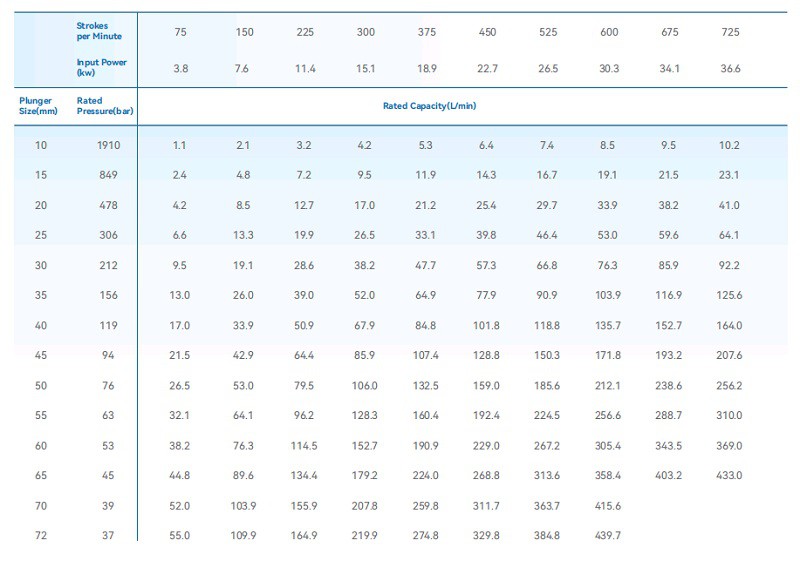

· Detailed Parameters:

Plunger Diameter: 10 mm

Pump Speed: 336 rpm

Theoretical Flow Rate: 4.75 L/min

Effective Power: 13.59 kW

· Drive Power and Method:

Base Type: Fixed base frame

Drive Type: Gear direct drive

Motor Type: Variable frequency motor

· Medium Contact Material:

Fluid End Cylinder: 630

Valve Assembly: 17-4PH

Plunger: 630 coated with tungsten carbide

Product Parameters

|

3DP60 |

|

|

|

Pump type: 3DP60 |

|

Pressure (bar): 150 Mpa |

|

|

Flow rate (L/min): 3.5 L/min |

|

|

Motor power (KW): 15 KW 6-pole |

|

|

Medium: Water |

|

|

Medium temperature ℃: Normal |

|

|

Valve accessories configuration: 1.Vibration-Resistant Pressure Gauge 2.Safety Relief Valve 3.Manual Relief Valve 4.Check Valve |

|

Working Principle

The high-pressure plunger pressure testing pump operates based on a reciprocating plunger mechanism. During the suction stroke, the plunger creates a vacuum, drawing fluid into the pump. On the forward stroke, the plunger compresses the fluid, generating high pressure, which is then expelled through the discharge outlet. This mechanism allows for precise pressure control, making it ideal for testing the integrity of pipes, tanks, and other systems.

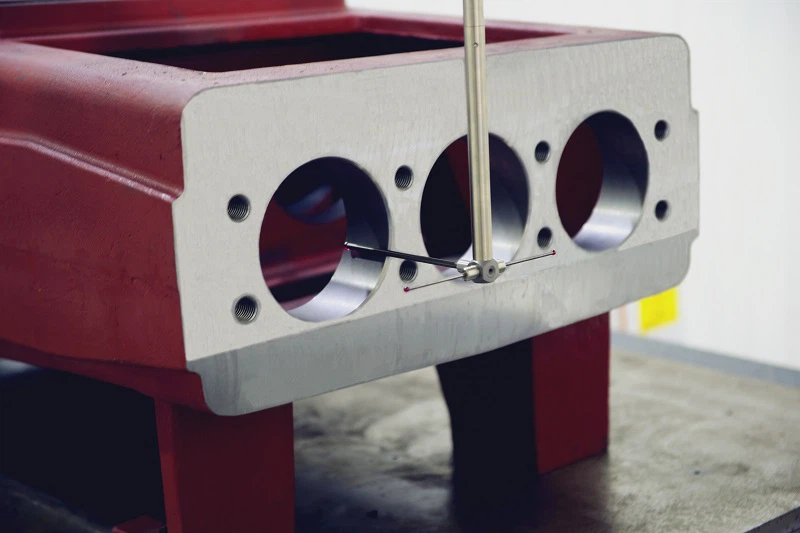

Product Composition

1. Pump Head: These valves ensure that fluid is drawn into the pump chamber during the suction stroke and then pushed out during the discharge stroke.

2. Motor or Drive Mechanism: In an electric pump, the motor provides the power to operate the piston or plunger. The speed and torque characteristics of the motor determine the pumping rate and the maximum pressure that can be achieved.

3. Pressure Gauge: An important component that displays the pressure applied to the test object.

4. Reservoir: A storage tank for hydraulic oil. It provides fluid supply to the pump and also allows any excess fluid to be returned during the test.

Advantages

1. They have high reliability and stability. They are carefully designed and manufactured to maintain stable performance under various working conditions, ensuring the accuracy and reliability of the testing process.

2. Hydro pressure testing pumps have efficient performance. They can quickly establish and maintain the required pressure, saving time and improving work efficiency.

3. They have a high pressure range and flow capacity, which can meet the needs of different application areas.

4. Hydro pressure testing pumps are usually designed with compact structure and small size, which is easy to carry and operate.

5. They have a long service life and stable performance. After good maintenance and care, hydro pressure testing pumps can operate stably for a long time and provide users with long-lasting and reliable services.

Application Fields

· Pipeline Pressure Testing: Ideal for testing the integrity of pipelines in the oil and gas industry, as well as other fluid systems.

· Pressure Vessel Testing: Ensures the safety and reliability of pressure vessels used in industrial and chemical plants.

· Hydraulic System Testing: Suitable for testing the performance and durability of hydraulic systems and components.

· Industrial Quality Control: Used in manufacturing and production lines to verify the pressure resistance of various products and equipment.

testing equipment

Processing Equipment

Hot Tags: hydro pressure testing pump, China hydro pressure testing pump manufacturers, suppliers, factory