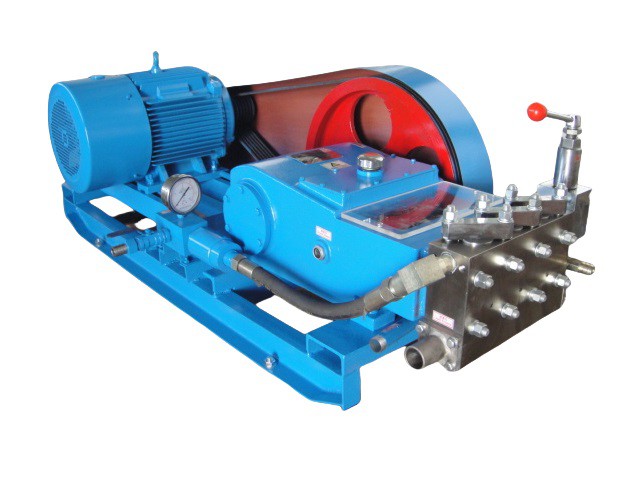

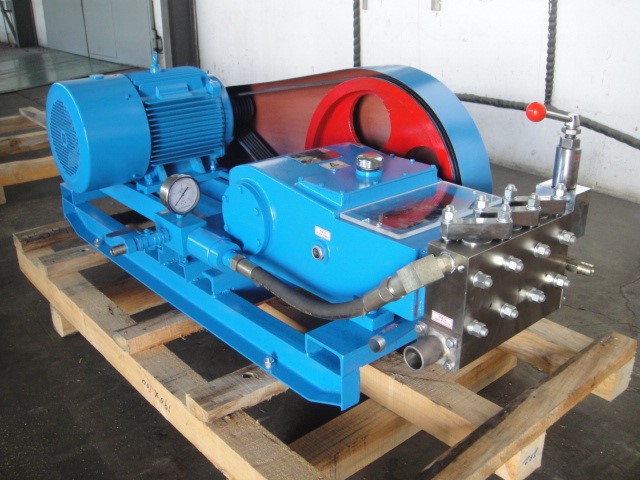

The electric pressure test pump is a device that generates pressure using an electric motor. It can successfully test the integrity and pressure resistance of pipelines, valves, boilers, and other hydraulic systems. Using electricity, the pump can provide a controlled high-pressure water flow, which is critical for determining the waterproofness of various systems. It is an essential component in industries such as pipelines, heating, fire prevention, oil and gas, and construction.

Product Details

Product Details

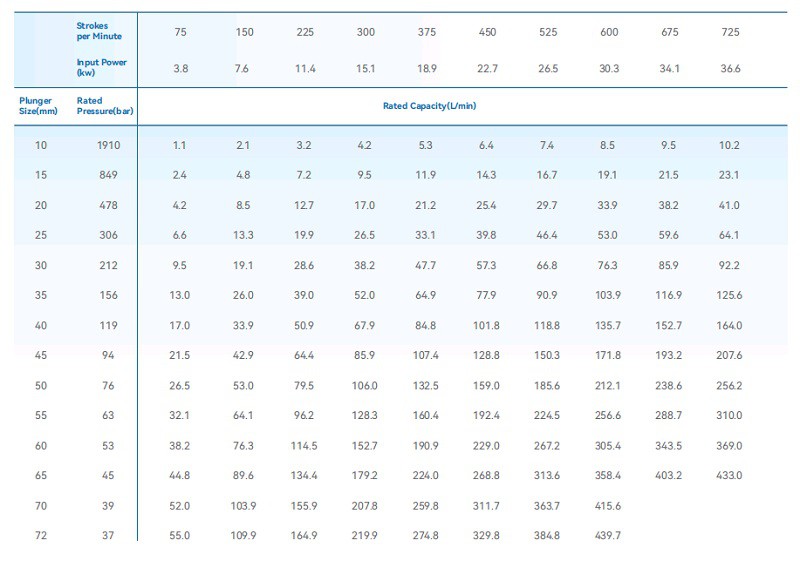

· Detailed Parameters:

Plunger Diameter: 52mm

Pump Speed: 262rpm

Theoretical Flow Rate: 100.15L/min

Effective Power: 16.09KW

· Drive Power and Method:

Fixed chassis design ensures stable and secure operation.

Belt-driven system powered by an 18.5KW four-pole standard motor, providing reliable and efficient performance.

· Media Contact Materials:

Hydraulic End Cylinder: Made from 45 steel with nickel plating, offering enhanced corrosion resistance and durability.

Valve Assembly: Constructed from 2Cr13, known for its high strength and excellent resistance to wear and corrosion.

Plunger: Crafted from 45 steel with a Ni60 coating, providing superior wear resistance and longevity under extreme pressure conditions.

Product Parameters

|

3DP60 |

|

|

|

Pump type: 3DP60 |

|

Pressure (bar): 8 Mpa |

|

|

Flow rate (L/min): 100 L/min |

|

|

Motor power (KW): 18.5 KW 4-pole |

|

|

Medium: Water |

|

|

Medium temperature ℃: Normal Temperature |

|

|

Valve accessories configuration: 1.Manual Pressure Relief Valve 2.Relief Valve 3.Vibration-resistant Pressure Gauge 4.Check Valve |

|

Main functions

1. Pressure test: used to test the pressure resistance of equipment such as pipelines, valves, and pressure vessels to ensure that they will not leak or break during use.

2. Efficient pressurization: through electric drive, it can provide high pressure output stably and accurately, which is convenient for rapid testing.

3. Liquid and gas testing: It can be used for pressure testing of different media such as water, oil, and gas, and is suitable for a variety of industry needs.

4. Automatic control: Electric Pressure Test Pump has an automatic control system that can automatically stop or adjust the pressure according to the set pressure to avoid overpressure.

Advantages

1.Efficiency: Electric Pressure Test Pump provides enhanced efficiency and precision.

2.Precision: Ability to maintain consistent and controlled pressure levels.

3.Automation: Automation reduces the risk of human error, resulting in more accurate and reliable test results.

4.Safety: Including automatic high-pressure cut-off mechanism, pressure relief valve and emergency stop button, providing comprehensive protection.

Application Fields

1. Pipeline: Detect leaks in water/gas pipelines.

2. HVAC: Check refrigerant lines, boilers and heat exchangers.

3. Manufacturing: Quality control of valves, cylinders or hydraulic systems.

4. Automotive: Fuel system, radiator or air conditioner.

5. Aerospace/Energy: Pressure vessel certification (ASME, PED standards).

Precautions for using an electric pressure test pump

1. Before use, tighten the switch clockwise.

2. The working medium used must be filtered through a 100 mesh/inch filter before it can be injected into the water tank, and the suction port must not leak water.

3. It must not be used in workplaces with acids, alkalis and corrosive substances.

4. After stopping use, use kerosene or kerosene as the medium for filtration.

Instructions for use of electric pressure test pump

1. Check whether the gasket and joints are well matched and correctly connect the water inlet pipe;

2. Before use, the live wire and ground wire must be correctly connected, and they must not be connected incorrectly! The power cord should be connected to a socket with leakage protection.

3. Loosen the pressure adjustment knob first, and do not start the motor with load to avoid damaging the motor

4. Check the filter regularly to avoid clogging

5. If the water pump cannot suck water, add a certain amount of water to the water pump from the water inlet pipe.

6. Prevent air from entering the water pump.

7. After the pressure test, loosen the pressure regulating knob, add a little 20# engine oil, keep it loose, turn on the power at the same time, add oil at the water inlet and run for half a minute.

8. It is strictly forbidden to start the machine without water, otherwise the seal ring and piston ring are easy to be damaged.

9. The water source must not have impurities, otherwise it is easy to jam the seal ring, resulting in the phenomenon of not being able to suck water.

10. Water leakage at the bottom of the pump body indicates that the seal ring is damaged and must be replaced.

11. Please use the pressure regulating button correctly and do not turn the pressure regulating knob to the bottom, otherwise the pressure is too high and the instrument is damaged.

Quality Testing Equipment

Hot Tags: electric pressure test pump, China electric pressure test pump manufacturers, suppliers, factory