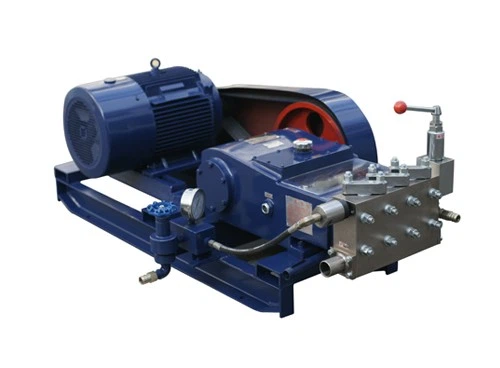

The High Pressure Test Pump is a device used to test high-pressure liquid systems on pipes, valves, vessels, and other equipment. This type of pump is commonly used for pressure testing and calibration work in industry, chemicals, oil, gas, pharmaceuticals and other fields. The working principle of a high-pressure test pump is to test whether the equipment can withstand pressure within its design pressure range by increasing the pressure of the fluid.

Product Details

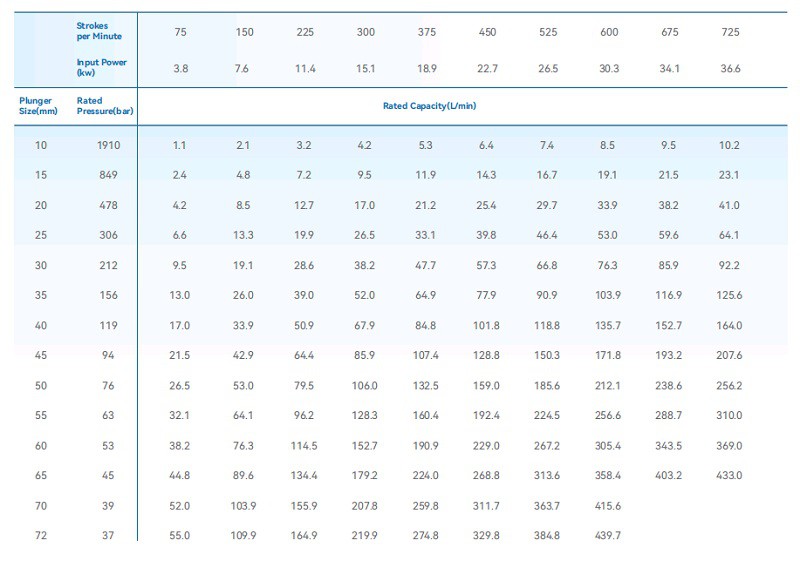

Product Parameters

Please visit our official website to view the complete range of parameters and specifications:https://www.hygyb.com/en/prolist/20

|

3DP60-Case 1 |

|

|

|

Pump Number: 20200937 |

|

Pump Type: 3DP60 |

|

|

Pressure (bar): 1000bar |

|

|

Flow (L/min): 7.5L/min |

|

|

Motor Power (KW): 15KW |

|

|

Medium: Water |

|

|

Medium Temperature ℃: Normal Temperature |

|

|

Valve Accessory Configuration: 1.Overflow Valve HY-Y18KA-00A 2.Pressure Relief Valve 20UV61V (Manual) 3.Check Valve 20SC46 |

|

|

3DP60-Case 2 |

|

|

|

Pump Number: 20200875 |

|

Pump Type: 3DP60 |

|

|

Pressure (bar): 600bar |

|

|

Flow (L/min): 15L/min |

|

|

Motor Power (KW): 22KW |

|

|

Medium: Water |

|

|

Medium Temperature ℃: Normal Temperature |

|

|

Valve Accessory Configuration: 1.Overflow Valve HY-Y18K-00A 2.Pressure Relief Valve HY-JF1-00 3.Check Valve HY-ZH1-00B |

|

|

3DP60-Case 3 |

|

|

|

Pump Number: 20200848 |

|

Pump Type: 3DP60 |

|

|

Pressure (bar): 1000bar |

|

|

Flow (L/min): 7L/min |

|

|

Motor Power (KW): 15KW |

|

|

Medium: Water |

|

|

Medium Temperature ℃: Normal Temperature |

|

|

Valve Accessory Configuration: 1.Overflow Valve HY-Y18K-00A 2.Pressure Relief Valve 20UV61V 3.Check Valve 20SC46 |

|

|

3DP60-Case 4 |

|

|

|

Pump Number: 20190839 |

|

Pump Type: 3DP60 |

|

|

Pressure (bar): 2000 |

|

|

Flow (L/min): 2 |

|

|

Motor Power (KW): 11 |

|

|

Medium: Water |

|

|

Medium Temperature ℃: Normal Temperature |

|

|

Valve Accessory Configuration: 1.Overflow Valve HY-Y18KA-00 2.Pressure Relief Valve 60UV41V 3. Check Valve 60BC4 |

|

|

3DP60-Case 5 |

|

|

|

Pump Number: 20181154 |

|

Pump Type: 3DP60 |

|

|

Pressure (bar): 200 |

|

|

Flow (L/min): 36.7 |

|

|

Motor Power (KW): 22 |

|

|

Medium: Water |

|

|

Medium Temperature ℃: Normal Temperature |

|

|

Valve Accessory Configuration: 1.Overflow Valve HY-Y18KA00A 2.Pressure Relief Valve HY-JF2-00 3.Check Valve HY-ZH1-00 |

|

|

3DP60-Case 6 |

|

|

|

Pump Number: 20151210 |

|

Pump Type: 3DP60 |

|

|

Pressure (bar): 300 |

|

|

Flow (L/min): 30 |

|

|

Motor Power (KW): 18.5 |

|

|

Medium: Clear Water |

|

|

Medium Temperature ℃: Normal Temperature |

|

|

Valve Accessory Configuration: 1.Overflow Valve HY-18K-00 2.Foot Valve HY-JF1-00 3.One-way Valve HY-ZH1-00A |

|

Product composition

High Pressure Test Pump usually consists of a pump body, a pressure gauge, a pressure relief valve and an output pipeline. Users can control pump operation manually or automatically to adjust output pressure when required. High-pressure test pumps are typically capable of generating pressures from thousands to tens of thousands of psi to meet the testing needs of different equipment.

Work steps

1. Preparation: Check whether all parts of the pump are intact and ensure that the pump body and pipes are not leaking or damaged.

2. Connect the equipment: Connect the High Pressure Test Pump to the equipment to be tested, making sure the connection is firm.

3. Set the pressure: Adjust the pump output pressure according to the requirements of the equipment and monitor the reading on the pressure gauge.

4. Perform the test: Start the pump, increase the pressure until the test pressure for which the equipment is designed, and hold for a period of time to ensure that the equipment is stable.

5. Result recording: Record the pressure data during the test for subsequent analysis and reference.

Feature

1. High pressure output: High pressure test pumps can provide high pressure output up to hundreds of megapascals (MPa), usually up to 100 MPa or higher, and even more than 200 MPa.

2. Stability and precision: High-pressure test pumps should maintain stable output pressure. Typically, accurate pressure regulating devices are employed to maintain a smooth output of pressure and minimize extreme changes during the test, which can impact the results.

3. High-pressure test pumps often offer adjustable flow. Users can adjust the flow outputs as needed to run testing under various situations.

4. High-pressure test pumps typically employ corrosion-resistant materials like stainless steel to maintain steady performance while handling corrosive liquids.

5. Safety: High-pressure pumps are typically equipped with a number of safety systems, including overload protection, pressure relief valves, pressure gauges, and so on, to protect the pump body from damage caused by excessive pressure and to assure operator safety.

Advantage

1. Accuracy: The High Pressure Test Pump is able to precisely control pressure levels during testing, ensuring that the system is fully tested and does not exceed safety limits.

2. Safety: Built-in safety features such as pressure relief valves and pressure gauges help protect operators and systems from dangerous overpressure.

3. Durability: This High Pressure Test Pump can operate trouble-free at high pressures.

4. Versatility: The High Pressure Test Pump is suitable for a variety of industries and applications, from pipeline testing to industrial equipment pressure testing.

Maintenance and precautions

1. Inspect and maintain the pump periodically to prevent leaks.

Clean impurities and sediments from the pump to prevent harm.

Check that essential components like pressure gauges and pressure relief valves are functioning properly.

2. Liquid selection: Ensure the liquid is appropriate for high-pressure testing. Some liquids may be caustic and require careful handling.

To maintain effective sealing and liquid pressure delivery, keep air out of the pump body while in use.

3. Safe operation: Use the High Pressure Test Pump with caution to avoid damaging the equipment if it exceeds its safety range.

Operators should undergo expert training to ensure proper pump operation and fast response to crises.

Installation steps

1. Preparation: Ensure all necessary tools and supplies are available for installation. Check the equipment and pipes for integrity and completeness.

2. Choose a flat and solid area to install the high-pressure test pump. Make sure there is enough room around the place for operation and that the necessary pipes and power supplies can be easily connected.

3. Connect pipes: Connect input and output pipes as per equipment design. Make sure the pipes are securely connected and apply sealants or gaskets to prevent water leaks.

4. Connect the power supply: Connect the high-pressure test pump to a suitable power source. Ensure that the power supply meets the equipment's needs and is connected in accordance with proper electrical installation practices.

5. Fill the pump with the suitable medium, such as water or lubricating oil, based on the equipment specifications. Check that the amount of medium meets the equipment specifications and does not exceed the maximum allowed.

6. Check the pressure gauge for correctness and regular operation. If necessary, adjust the pressure gauge to ensure that the pressure figure displayed is accurate.

7. Start the test pump: After completing preparations, start the high-pressure test pump and monitor its operation. Check that the pump is working properly, with no strange noises or leaks.

8. Test: Ensure the high-pressure test pump generates and maintains the specified pressure.

9. Maintenance and Care: Regularly inspect and maintain the high pressure test pump to ensure optimal performance. Follow the manufacturer's maintenance requirements to extend the life of the equipment.

our factory

Hot Tags: high pressure test pump, China high pressure test pump manufacturers, suppliers, factory