A hydraulic pressure test pump is a specialized piece of equipment used to test the hydraulic pressure of pipelines, valves, and containers. It is made up of several parts, including the pump body, pressure gauge, control valve, and relief valve. It is both durable and efficient. It is typically used to assess the sealing performance and pressure resistance of equipment in order to assure its safety and dependability during operation. It is utilized in the manufacturing, construction, oil and gas, aerospace, and automotive sectors.

Product Details

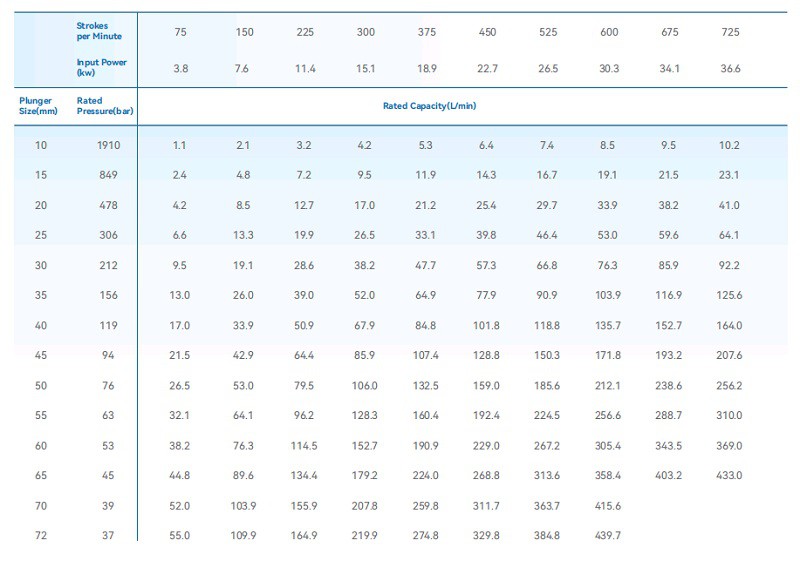

Product Parameters

|

3DP60 |

|

|

|

Pump type: 3DP60 |

|

Pressure (bar): 30 Mpa |

|

|

Flow rate (L/min): 20 L/min |

|

|

Motor power (KW): 15 KW 4-pole |

|

|

Medium: Water |

|

|

Medium temperature ℃: Normal Temperature |

|

|

Valve accessories configuration: 1.Manual Pressure Relief Valve 2.Relief Valve 3.Vibration-resistant Pressure Gauge 4.Check Valve |

|

Working Principle

1. Preparation: Fill the reservoir with hydraulic oil and connect the pump to the system under test.

2. Pressurization: Operate the pump to gradually increase pressure until the desired level is reached.

3. Testing: Maintain pressure for a specified period of time to evaluate the performance of the system.

4. Analysis: Monitors any pressure drops or leaks, which indicate potential problems.

Feature

- Safety: Allows for thorough testing without risking system failure during operation.

- Efficiency: Provides a fast and reliable way to check system integrity.

- Cost-effective: Helps prevent costly downtime and repairs by identifying problems early.

- Versatility: Can be used in a variety of hydraulic systems and components.

Advantage

- Quality Assurance: Ensures that the hydraulic system meets specified performance standards.

- Maintenance: Helps identify and correct leaks or weaknesses before they cause system failures.

- Commissioning: Verifies the functionality of newly installed hydraulic components.

- Troubleshooting: Assists in diagnosing problems in existing hydraulic systems.

Common applications

1. Pipeline and valve testing: Ensure that newly installed or repaired pipes and valves can withstand the working pressure.

2. Pressure vessel testing: Gas cylinders, storage tanks, etc. require pressure testing.

3. Industrial system testing: Applicable to the testing of various mechanical equipment such as hydraulic systems and cooling systems.

Considerations

- Pressure range: Make sure the pump can produce the required pressure level for your specific application.

- Accuracy: Choose a pump with an accurate pressure gauge for reliable testing.

- Portability: Choose a pump that is easy to transport and set up on site.

- Durability: Look for rugged construction to withstand frequent use in demanding environments.

Storage method

1. Storage location: Place the hydraulic pressure test pump in a dry, well-ventilated area.

2. Protect the pump's outside surface: Use a dust cover or pump sleeve to keep dust, grime, and other contaminants out of the pump.

3. Oil treatment: If the hydraulic test pump requires oil, drain it or replace it with clean oil before storing.

4. Keep the pump stationary: To avoid damage or issues, do not move or handle the hydraulic pressure test pump too frequently while in storage.

5. Regular inspection: Inspect the stored pump on a regular basis to ensure it is free of damage or abnormalities.

6. Adhere to the manufacturer's recommendations: Follow the manufacturer's particular storage requirements.

certificate

our factory

Hot Tags: hydraulic pressure test pump, China hydraulic pressure test pump manufacturers, suppliers, factory