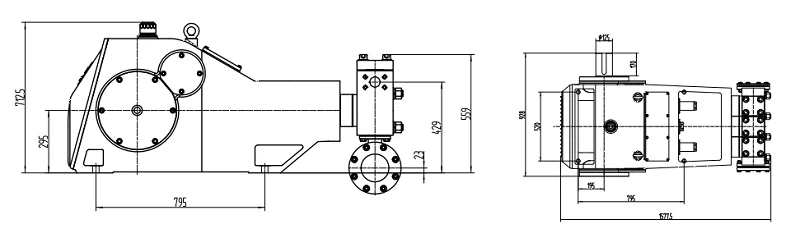

High pressure triplex plunger pump is a device used to generate high-pressure water flow, commonly used in industrial and commercial applications. This type of pump consists of three plungers and three cylinders, which produce high-pressure water flow through reciprocating motion.

Product Details

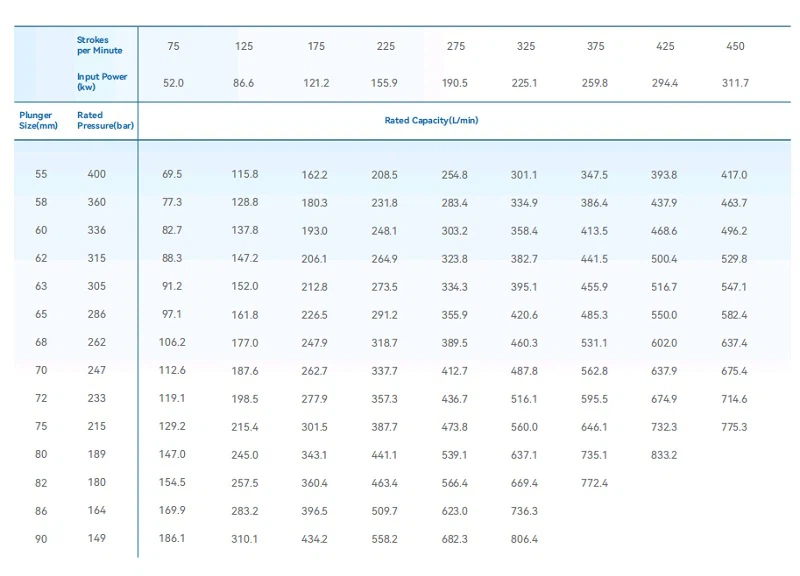

Product Parameters

Please visit our official website to view the complete range of parameters and specifications:https://www.hygyb.com/en/prolist/20

|

3ZH130-Case 1 |

|

|

|

Pump number: 20170635 |

|

Oil pool filling volume: 72.6L |

|

|

Pump thrust: 9500kg(ibs.) |

|

|

Import pressure: 0.2~0.5Mpa |

|

|

Single pump weight: 941kg |

|

|

3ZH130-Case 2 |

|

|

|

Pump number: 202007101 |

|

Oil pool filling volume: 72.6L |

|

|

Pump thrust: 9500kg(ibs.) |

|

|

Import pressure: 0.2~0.5Mpa |

|

|

Single pump weight: 941kg |

|

Working principle

The working principle of the High pressure triplex plunger pump is based on the reciprocating motion of the plunger in the cylinder. As the plunger moves rearward, it creates a low-pressure area within the cylinder, which draws in liquid. The plunger then moves forward, pushing liquid into the pipe and creating a high-pressure flow of water. This design allows the pump to produce high efficiency and high pressure water flow.

Advantage

- High-pressure output: capable of generating extremely high water pressure, suitable for various high-pressure applications.

- High efficiency: Due to its exquisite design, it provides efficient water delivery.

- Durable: Usually made of durable materials that can withstand high pressure and frequent use.

- High reliability: Stable performance makes it the first choice in many industrial and commercial fields.

Maintenance precautions

1. Regularly check the pump's operational condition and performance to ensure that it is operating normally.

2. Maintain the pump's cleanliness by cleaning the inside and outside on a regular basis to avoid contaminants from entering the pump and interfering with its operation.

3. Examine the seals and sealing performance of the pump to ensure that it is properly sealed to prevent leakage.

4. Check the pump's lubrication system on a regular basis to ensure that the lubricating oil is sufficient and clean, hence reducing wear.

5. Monitor the pump's temperature and pressure to ensure that it runs safely.

6. Ensure that the pump's wearing parts, such as seals, pistons, and so on, are replaced on a regular basis to ensure proper operation.

7. If an abnormal noise or vibration is detected, the pump should be stopped immediately and fixed.

Storage and maintenance

Cleaning and drying treatment:

Before stopping the pump, it should be properly cleaned to remove any remaining oil, pollutants, and other contaminants from the surface and inside of the pump body, and then dried naturally or blown dry to prevent the residual substances from corroding the parts.

For some metal items that are prone to rust, add an adequate amount of anti-rust oil to provide protection.

Proper storage environment:

To prevent rusting and aging of the pump body and parts, store them in a dry, well-ventilated place at an appropriate temperature. Avoid storing them in a humid, high-temperature, corrosive gas environment.

If the pump is stored for an extended period of time, it should be inspected on a regular basis for simple appearance and manually turned for spinning sections to prevent them from becoming stuck due to static buildup.

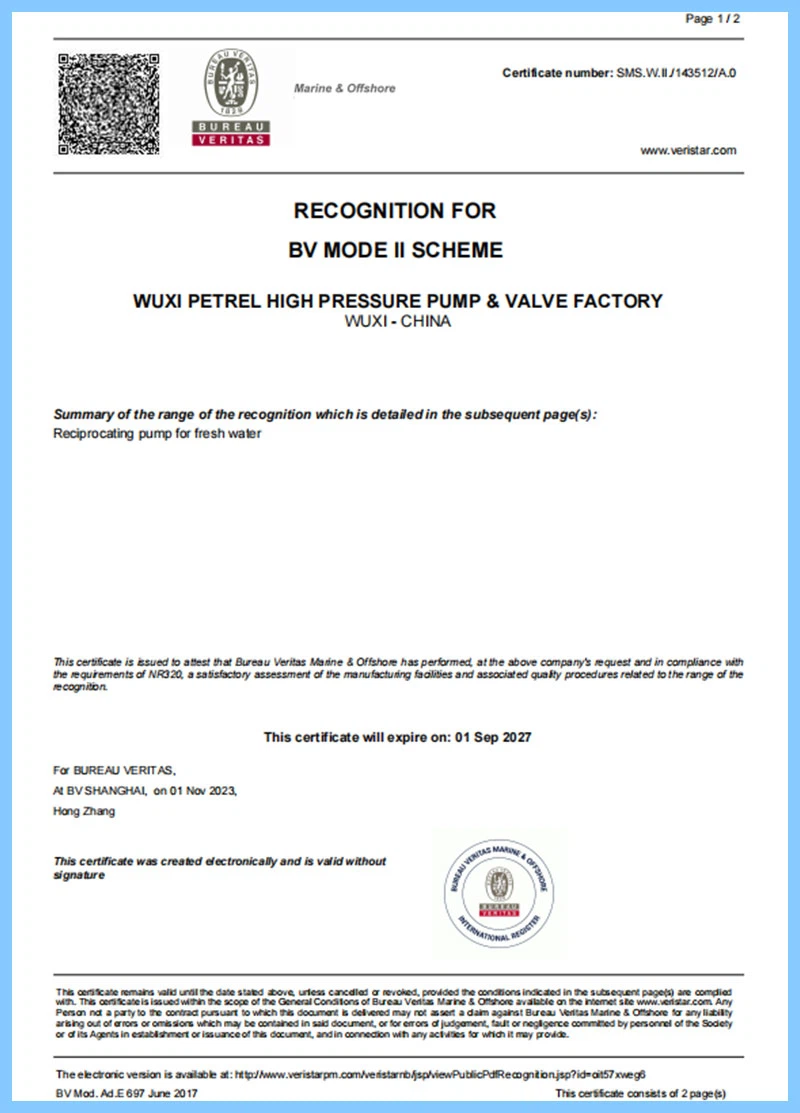

certificate

Processing Equipment

Hot Tags: high pressure triplex plunger pump, China high pressure triplex plunger pump manufacturers, suppliers, factory