Horizontal chemical pump is a device used to transport chemical liquids, usually driven by an electric motor. This pump is designed to handle a variety of chemicals such as acids, alkalis, solvents, etc. in industrial and laboratory settings. They are usually made of corrosion-resistant materials to ensure reliability and safety when handling corrosive substances.

Product details

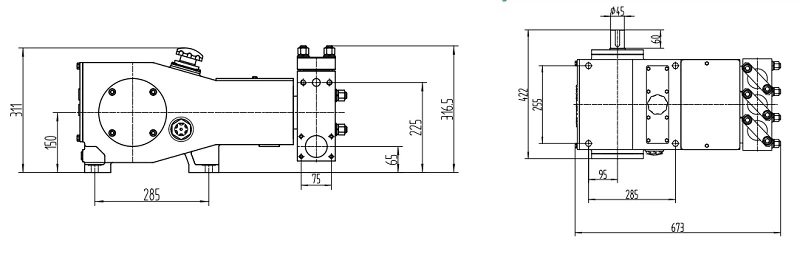

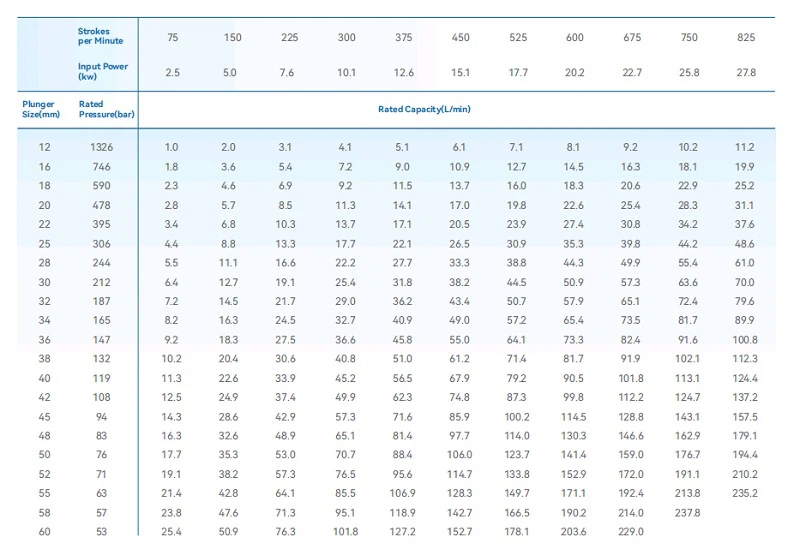

Product Parameters

Please visit our official website to view the complete range of parameters and specifications:https://www.hygyb.com/en/prolist/20

|

3ZX40-Case 1 |

|

|

|

Pump number: 20210532 |

|

Pump type: 3ZX40 |

|

|

Pressure (bar): 145bar |

|

|

Flow rate (L/min): 25L/min |

|

|

Motor power (KW): 11KW |

|

|

Medium: desalted water |

|

|

Medium temperature ℃: normal temperature |

|

|

Valve accessories configuration: 1. Safety valve A22Y-160P DN40 2. Pressure relief valve HY-JF2-00 3. Accumulator NXQ1-L0.32/16 4. Accumulator NXQ1-L0.32/16 |

|

|

3ZX40-Case 2 |

|

|

|

Pump number: 20170406 |

|

Pump type: 3ZX40 |

|

|

Pressure (bar): 40bar |

|

|

Flow rate (L/min): 45.1L/min |

|

|

Motor power (KW): 5.5KW |

|

|

Medium: clean water |

|

|

Medium temperature ℃: 80℃ |

|

|

Valve accessories configuration: 1. Safety valve A22Y-63P DN15 2. Pressure relief valve HY-JF2-00 |

|

Feature

1. Energy efficiency: The Horizontal Chemical Pump with Electric Motor may optimize energy by modifying the impeller to meet the needs of specific customers and industries, as well as using efficient drives.

2. Variability: Based on a thorough modular design approach, it can adapt to clients' diverse process system needs by offering a number of material alternatives and impeller and sleeve types.

3. Operational reliability: The Horizontal Chemical Pump with Electric Motor has a sturdy structure, produces less axial thrust, and has superior hydraulic characteristics, resulting in quiet and smooth operation.

4. Strong corrosion resistance: The pump body, impeller, and other essential components are generally comprised of corrosion-resistant metals, which significantly extends the equipment's service life.

5. Adjustable flow and head: The horizontal chemical pump's flow and head may be easily altered by modifying the motor speed, impeller diameter, and other factors.

6. High operating stability: It uses high-quality bearings, sealing devices, and other components while also paying attention to the entire structure's stability, resulting in high stability.

7. Simple maintenance: The structure is obvious, the key components are easy to recognize and use, and it is simple to maintain.

Precautions

First, operators must wear appropriate protective gear such as gloves, goggles, and protective clothing to prevent injury from chemical splashes.

Secondly, regularly check the condition of the pump body and seals to ensure normal operation.

Finally, select the appropriate pump type and material according to the properties of the chemical liquid to ensure the stability and durability of the pump.

Installation and maintenance tips

1. Foundation: Use a rigid base plate and inject epoxy grout to minimize vibration.

2. Alignment: Laser align motor/pump shaft (tolerance less than 0.05 mm).

3. Piping: Avoid nozzle stress; use expansion joints if necessary.

4. Priming: Ensure that the suction inlet is fully submerged (NPSH<sub>A</sub> > NPSH<sub>R</sub> + 1 meter).

5. Monitoring: Install vibration/temperature sensors for predictive maintenance.

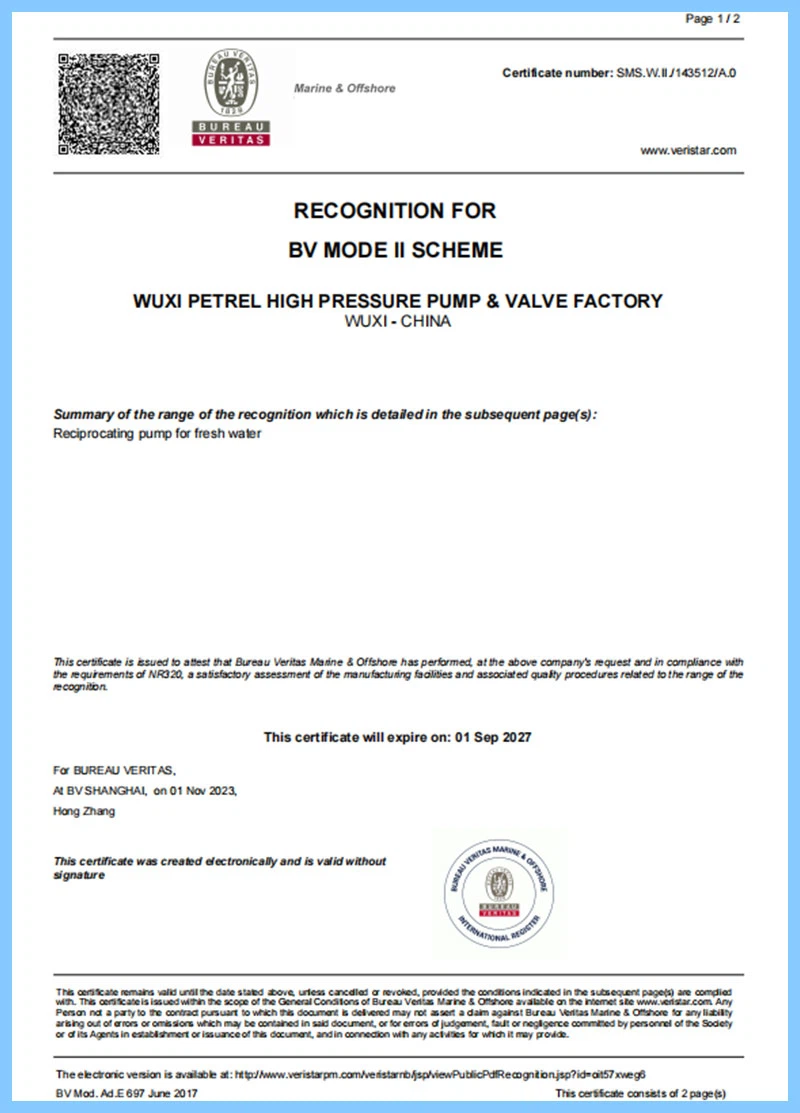

certificate

Hot Tags: horizontal chemical pump with electric motor, China horizontal chemical pump with electric motor manufacturers, suppliers, factory