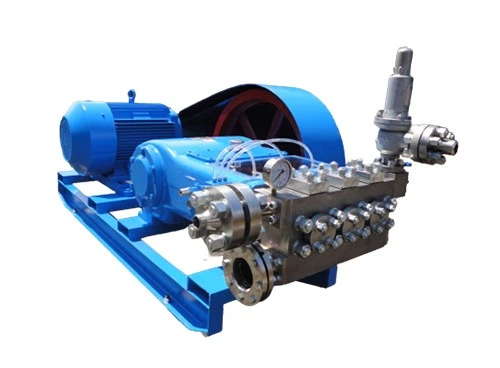

The Stainless Steel Chemical Process Pump is a pump designed specifically for the chemical industry and is commonly used to transport corrosive liquids, high temperature liquids, or liquids with special chemical properties. It is usually made of stainless steel, corrosion-resistant, high temperature-resistant, and suitable for handling a wide range of chemicals. These pumps have revolutionized the chemical industry by being able to safely transport liquids, gases, and slurries from one place to another.

Product Parameters

Please visit our official website to view the complete range of parameters and specifications:https://www.hygyb.com/en/prolist/20

|

3DP120.100-Case 1 |

|

|

|

Pump number: 20210603 |

|

Pump type: 3DP120.100 |

|

|

Pressure (bar): 250bar |

|

|

Flow rate (L/min): 167L/min |

|

|

Motor power (KW): 90KW |

|

|

Medium: water |

|

|

Medium temperature ℃: normal temperature |

|

|

Valve accessories configuration: 1. Safety valve A41Y-320C DN32 2. Pressure relief valve HY-JF2-00 |

|

|

3DP120.100-Case 2 |

|

|

|

Pump number: 20171109 |

|

Pump type: 3DP120.100 |

|

|

Pressure (bar): 250 |

|

|

Flow rate (L/min): 145 |

|

|

Motor power (KW): 90 |

|

|

Media: polymer |

|

|

Medium temperature ℃: 40 |

|

|

Valve accessories configuration: safety valve A21T-500H |

|

Feature

1. Corrosion resistance: It is made of stainless steel, which can withstand corrosion from a variety of chemical media.

2. High efficiency: well-designed, capable of delivering consistent flow and pressure.

3. Reliability: long-term stable functioning with reduced maintenance requirements.

4. Safety: features an effective sealing design to prevent leaks and mishaps.

5. Broad applicability: Pumps of various specifications and configurations can be tailored to meet unique needs.

Advantage

1. Corrosion resistance: Stainless steel materials are resistant to acids, alkalis, salts, and solvents, allowing the pump to operate reliably and long-term in a variety of chemical situations.

2. Low maintenance and extended life: Stainless steel chemical process pumps have high wear and oxidation resistance, which reduces wear, extends pump life, and lowers maintenance expenses.

3. High efficiency: Design optimization improves the pump's efficiency, stabilizes output flow and pressure, and reduces energy consumption.

4. Safety: The material's corrosion resistance reduces the risk of leakage and contamination, while increasing operational safety.

Application

1. Chemical production: used for the transportation and circulation of chemical substances.

2. Food production: used in the food processing industry for the processing of food raw materials and cleaning.

3. Pharmaceutical development: used in the pharmaceutical industry for the processing of drug raw materials and cleaning.

4. Oil production: used for the transportation of oil and related products.

5. Water treatment: used for seawater desalination and reverse osmosis systems.

6. Agriculture: used in irrigation systems to help efficiently transport water.

Precautions for use

1. Pump installation: During installation, the connection between the pump and the pipeline should be ensured to be tight to avoid leakage and vibration.

2. Pump start and stop: Check whether the pump's rotation direction is correct before starting. When stopping, close the inlet valve first and then the outlet valve.

3. Pump maintenance: Regularly check the wear of the pump's seals, bearings, lubricating oil and other parts, and replace damaged parts in time.

4. Pump operation status: Regularly check the pump's operation status, such as abnormal conditions such as noise and vibration, and deal with them in time.

certificate

our factory

Hot Tags: stainless steel chemical process pump, China stainless steel chemical process pump manufacturers, suppliers, factory