The stainless steel horizontal chemical pump is a reliable and efficient solution for handling corrosive and abrasive liquids in a variety of industries including chemical processing, petrochemicals and pharmaceuticals. These pumps are specifically designed to handle corrosive and hazardous chemicals that standard pumps made of conventional materials cannot handle.

Product details

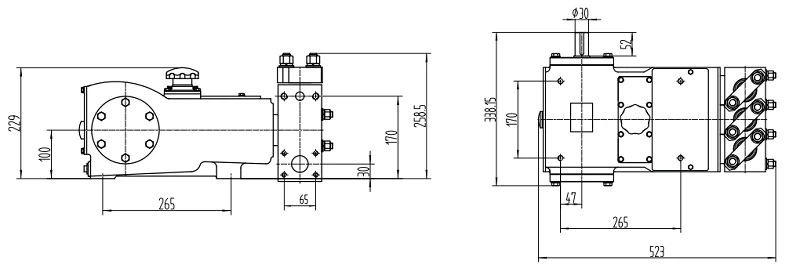

Product Parameters

Please visit our official website to view the complete range of parameters and specifications:https://www.hygyb.com/en/prolist/20

|

3DP35-Case 1 |

|

|

|

Pump number: 20201218 |

|

Pump type: 3DP35 |

|

|

Pressure (bar): 30 |

|

|

Flow rate (L/min): 19.5 |

|

|

Motor power (KW): 2.2 |

|

|

Medium: ethanol |

|

|

Medium temperature ℃: normal temperature |

|

|

Valve accessories configuration: 1. Safety valve A22Y-40RL DN25 2. Pressure relief valve HY-JF2-00 |

|

|

3DP35-Case 2 |

|

|

|

Pump number: 20200737 |

|

Pump type: 3DP35 |

|

|

Pressure (bar): 100bar |

|

|

Flow rate (L/min): 2.5L/min |

|

|

Motor power (KW): 1.1KW |

|

|

Medium: Lactose |

|

|

Medium temperature ℃: normal temperature |

|

|

Valve accessories configuration: 1. Relief valve HY-A1-00 2. Pressure relief valve HY-JF2-00 |

|

|

3DP35-Case 3 |

|

|

|

Pump number: 20170852 |

|

Pump type: 3DP35 |

|

|

Pressure (bar): 249bar |

|

|

Flow rate (L/min): 7.14L/min |

|

|

Motor power (KW): 4KW |

|

|

Medium: clean water |

|

|

Medium temperature ℃: normal temperature |

|

|

Valve accessories configuration: 1. Safety valve HY-A1-00 2. Pressure relief valve HY-JF2-00 |

|

|

3DP35-Case 4 |

|

|

|

Pump number: 20160119 |

|

Pump type: 3DP35 |

|

|

Pressure (bar): 13 |

|

|

Flow rate (L/min): 2.5 |

|

|

Motor power (KW): 1.5 |

|

|

Medium: dimethyl disulfide |

|

|

Medium temperature ℃: 40 |

|

|

Valve accessories configuration: safety valve A21F-320RL |

|

|

3DP35-Case 5 |

|

|

|

Pump number: 20160114 |

|

Pump type: 3DP35 |

|

|

Pressure (bar): 5 |

|

|

Flow rate (L/min): 11.7 |

|

|

Motor power (KW): 0.75 |

|

|

Medium: light oil |

|

|

Medium temperature ℃: 40 |

|

|

Valve accessories configuration: safety valve A41Y-16P DN20/20 |

|

Working principle

This type of pump is usually driven by an electric motor and uses a rotating impeller or vane to create negative pressure to draw in liquid. Liquid is pushed through the pump body, creating a flow. Pumps are designed to ensure high efficiency and corrosion resistance when handling chemical liquids. This type of pump is commonly used in industrial areas, including chemical, pharmaceutical and other industries that need to handle chemical liquids.

Advantage

1. Corrosion resistance. Stainless steel is a durable, reliable material that resists corrosion and wear, making it ideal for use with aggressive and corrosive liquids. This makes it ideal for handling a range of chemical solutions such as acids, solvents, bases and other chemicals.

2. Efficiency. These pumps are designed to provide high flow rates and high pressures with minimal energy consumption. This makes them ideal for use in applications where energy efficiency and cost-effectiveness are key considerations.

3. Easy to maintain. They require minimal maintenance and are able to withstand harsh environments, making them a highly reliable choice for any industrial application.

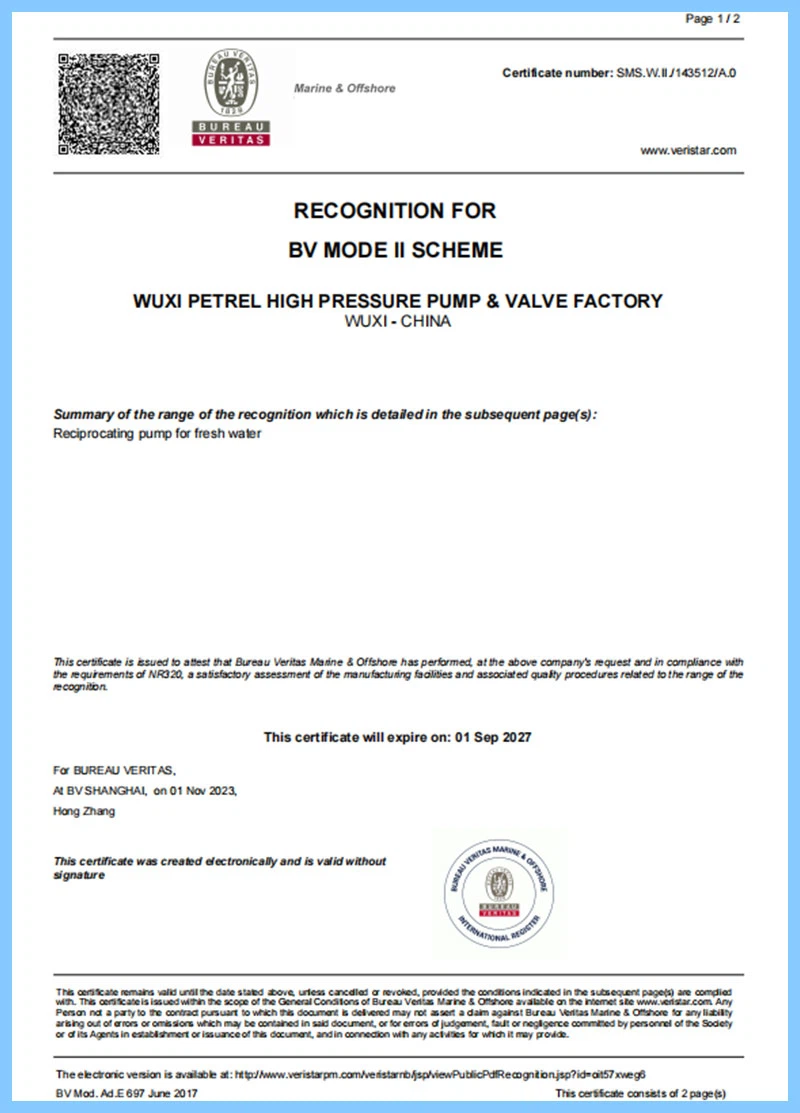

certificate

Hot Tags: stainless steel horizontal chemical pump, China stainless steel horizontal chemical pump manufacturers, suppliers, factory