Pumps For The Chemical Industry are pumps specifically designed to meet the unique requirements of chemical processing, including the transfer, circulation, and pressurization of chemicals, acids, solvents, and other potentially hazardous or reactive liquids. These pumps must be resistant to corrosion, wear, and sometimes even high temperatures, as they handle corrosive, often toxic or flammable substances.

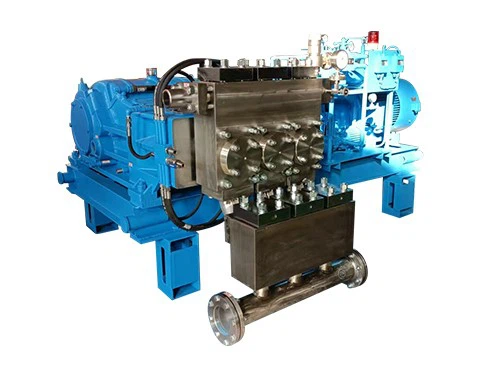

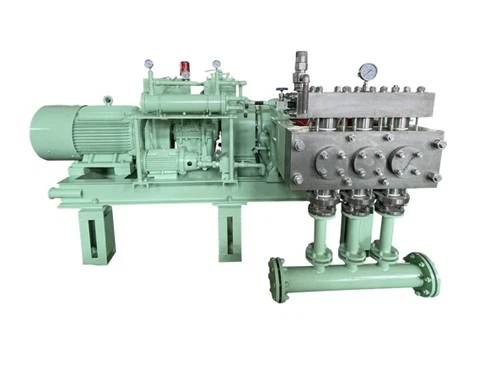

Product Details

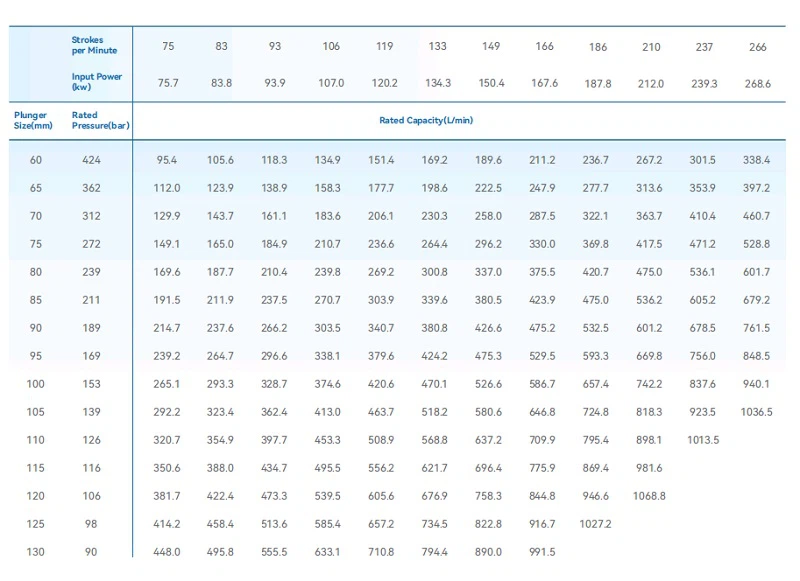

Product Parameters

Please visit our official website to view the complete range of parameters and specifications:https://www.hygyb.com/en/prolist/20

|

A150-Case 1 |

|

|

|

Pump number: 20211029 |

|

Pump type: A150 |

|

|

Pressure (bar): 80bar |

|

|

Flow rate (L/min): 284.1L/min |

|

|

Motor power (KW): 75KW |

|

|

Medium: monoammonium phosphate |

|

|

Medium temperature ℃: 110~140°C |

|

|

Valve accessories configuration: 1. Safety valve HY-A5-00 |

|

|

A150-Case 2 |

|

|

|

Pump number: 20201144 |

|

Pump type: A150 |

|

|

Pressure (bar): 110 |

|

|

Flow rate (L/min): 200.4 |

|

|

Motor power (KW): 55 |

|

|

Medium: aluminum silicate slurry |

|

|

Medium temperature ℃: 60℃ |

|

|

Valve accessories configuration: 1. Safety valve HY-A5-00 2. Pressure relief valve ball valve DN25 16MPa |

|

|

A150-Case 3 |

|

|

|

Pump number: 20160912 |

|

Pump type: A150 |

|

|

Pressure (bar): 200 |

|

|

Flow rate (L/min): 300 |

|

|

Motor power (KW): 100 |

|

|

Medium: softened water |

|

|

Medium temperature ℃: normal temperature |

|

|

Valve accessories configuration: safety valve HY-Y35PC-DD, accumulator NX13A-U6.3V10-F, accumulator NXQA-L20/O1.5-F, lubricating oil system |

|

|

A150-Case 4 |

|

|

|

Pump number: 20151001 |

|

Pump type: A150 |

|

|

Pressure (bar): 80 |

|

|

Flow rate (L/min): 384.1 |

|

|

Motor power (KW): 90 |

|

|

Medium: monoammonium phosphate |

|

|

Medium temperature ℃: 110~140 |

|

|

Valve accessories configuration: safety valve HY-A5-00 |

|

Feature

1. Corrosion Resistance

Chemical industry pumps are constructed from materials that can tolerate corrosive substances. Common materials include stainless steel, duplex stainless steel, high alloy steel, titanium, polymers (such as PTFE and polypropylene), and ceramics.

2. High pressures and flow rates.

Many chemical processes necessitate pumps that can withstand high pressures or flow rates, particularly in large-scale activities like chemical manufacture, refineries, and water treatment.

3. Leak-free operation.

Because the chemicals being delivered may be hazardous or toxic, chemical pumps frequently employ specialized seals, dual mechanical seals, or magnetic drive systems to prevent leaks.

4. Temperature Resistance.

Chemical pumps must be capable of handling fluctuating temperatures, particularly in operations that need fluid heating or cooling.

5. Safety features.

Because the chemicals used might be poisonous, flammable, or corrosive, safety measures including pressure relief valves, explosion-proof motors, and seal designs are crucial for preventing mishaps.

Advantage

1. Able to handle a variety of chemicals. Different chemicals require specific types of pumps, but the right pump can handle almost any liquid, gas or solid. This versatility is important in the chemical industry because it allows materials to be transported more efficiently.

2. Safe. Chemical transfer can be hazardous, but pumps are designed with safety features that reduce the risk of accidents. For example, many pumps have leak-proof seals and are made from corrosion- and wear-resistant materials.

3. Adaptability and efficiency. New technologies such as smart pumps are emerging to better monitor and control the chemical transfer process. These innovations make the chemical industry safer and more efficient.

Applications

1. Chemical Manufacturing: Pumps move raw materials and finished products between tanks, reactors, and packaging systems.

2. Water Treatment: Chemical dosing and metering pumps are used for drinking water and wastewater treatment.

3. Pharmaceuticals and Biotechnology: Precisely meter active ingredients during drug production.

4. Food and Beverage: Pump food-grade chemicals and detergents during production.

5. Oil and Gas: Handle and transfer corrosive drilling fluids, lubricants, and chemicals during refining.

Installation

1. Before proceeding with the installation, thoroughly read the manufacturer's instructions. These instructions normally offer thorough installation stages and precautions to assist you properly install the pump.

2. Select an acceptable installation location. Chemical industry pumps are often mounted on a sturdy base to ensure stable operation. At the same time, ensure that the pump is situated in a location that is easy to maintain and service.

3. Set up the pump stand or stand system. Install the stand according to the manufacturer's instructions, and ensure that it can sustain the pump's weight while remaining level.

4. Connect the pumps' inlet and output pipes. When connecting the pipes, make sure that the pipes are tightly linked and there are no water or air leaks. Also, make sure that the pipes are properly put out so that the pump can function effectively.

5. Connect and test the power supply. Before connecting the power supply, check that all electrical connections are properly installed. After connecting the power supply, start the pump and verify for operation.

Chemical pump selection recommendations

When selecting a chemical pump, the following factors need to be considered:

1. Fluid characteristics: including viscosity, flow rate, flammability, corrosiveness, abrasiveness and hazard level.

2. Design parameters: such as flow rate, required head, pressure and volume.

3. Material compatibility: Make sure the pump material is compatible with the chemicals being handled.

4. Maintenance and reliability: Choose a pump that is easy to maintain and has high reliability.

our factory

Hot Tags: pumps for the chemical industry, China pumps for the chemical industry manufacturers, suppliers, factory