Plumbing pressure test pump is a device that tests the integrity of a piping system by pressurizing the system to a certain level and checking for leaks. The plumbing pressure test pump is carefully designed to perform reliable pressure tests in a variety of industrial applications. A plumbing pressure test pump is a device that tests the integrity of a piping system by pressurizing the system to a certain level and checking for leaks. With its rugged construction and precise engineering design, our pumps provide consistent performance, making them ideal for testing and verifying pressure levels in critical systems.

Product Details

Product Details

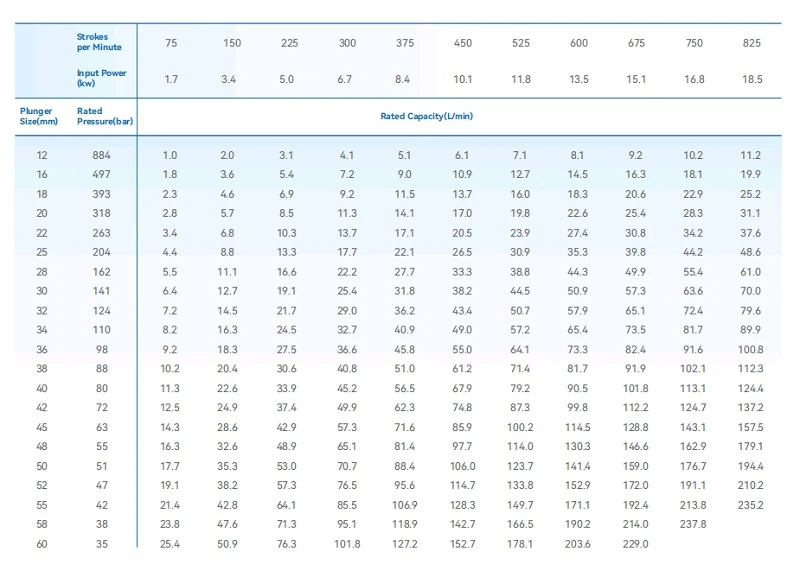

· Detailed Parameters:

Plunger Diameter: 12 mm

Pump Speed: 336 rpm

Theoretical Flow Rate: 4.56 L/min

Effective Power: 8.71 kW

· Drive Power and Method:

Base Type: Fixed base frame

Drive Type: Gear direct drive

Motor Type: Variable frequency motor

· Medium Contact Material:

Fluid End Cylinder: 630

Valve Assembly: 17-4PH

Plunger: 630 coated with tungsten carbide

Product Parameters

|

3DP40 |

|

|

|

Pump type: 3DP40 |

|

Pressure (bar): 100 Mpa |

|

|

Flow rate (L/min): 3.5 L/min |

|

|

Motor power (KW): 11 KW 6-pole |

|

|

Medium: Water |

|

|

Medium temperature ℃: Normal |

|

|

Valve accessories configuration: 1.Vibration-Resistant Pressure Gauge 2.Safety Relief Valve 3.Manual Relief Valve 4.Check Valve |

|

How to perform a pressure test

1. Attach the test pump: Attach the test pump to the pipe system's valve or test port.

2. Pressurize the system: To raise the system's pressure to the required test level, use a pump.

3. Keep an eye on the pressure: Verify the pressure gauge to make sure it stays constant throughout the test, which typically lasts 15 to 30 minutes.

4. Look for leaks: Look for indications of leakage in all visible pipe joints and fittings. A decline in pressure could be a sign of a leak.

5. Unplug and release pressure: After the test is over, unplug the test pump and gradually release the pressure.

Feature

1. The plumbing pressure test pump can operate in both pressurized and non-pressurized water supply settings and features an automated water diversion feature.

2. It can be used to test mild irrigation systems and is portable.

3. To lessen the chance of system overpressure, it has a safety valve.

4. It uses a sturdy steel operating handle, piston, and aluminum housing.

Precautions for use

Before use, check in detail whether the connections of each component are tightened, whether the pressure gauge is normal, and whether the inlet and outlet pipes are installed.

The working medium is 5~50°C clean water, emulsion or oiler with a kinematic viscosity of less than 45mm²/s. It is forbidden to use unclean water with silt and other contaminants.

Maintenance and care

1. Frequent cleaning: The key to maintenance is keeping the pump clean. Regularly clean the pump's internal and external components to make sure that no dust, grime, or other contaminants have accumulated.

2. Examine the seal: Verify that the pump seal is undamaged. To stop leaks, replace it as soon as wear or damage is discovered.

3. Lubrication: As directed by the manufacturer, apply lubricating oil or grease on a regular basis to the pump's working parts. This keeps the pump operating smoothly and lessens wear.

4. Examine the wires and power supply: To make sure there is no wear or damage, periodically examine the pump's cables and power connector. To prevent safety mishaps, stay away from using broken wires.

5. Regularly check the pressure gauge: Verify the pump's pressure gauge's accuracy. The pressure gauge should be promptly calibrated or replaced if it turns out to be erroneous.

6. Maintain steady use: Steer clear of overloading or overusing the pump. Avoid prolonged continuous operation and use in accordance with the instructions in the instruction manual.

7. Regularly inspect the pump's various components, such as the filters, valves, and pipe connections. Verify that there are no leaks or other issues and that every part is in good working order.

8. Conduct routine pressure testing: To make sure the pump is operating correctly and maintaining the necessary performance level, conduct routine pressure checks on it.

9. Precautions for storage: It is recommended to keep it in a dry, well-ventilated area and to clean and maintain it properly before storing it.

10. To guarantee long-term stable operation of the pump, perform routine maintenance, such as cleaning nozzles and replacing filter elements.

Processing Equipment

Hot Tags: plumbing pressure test pump, China plumbing pressure test pump manufacturers, suppliers, factory