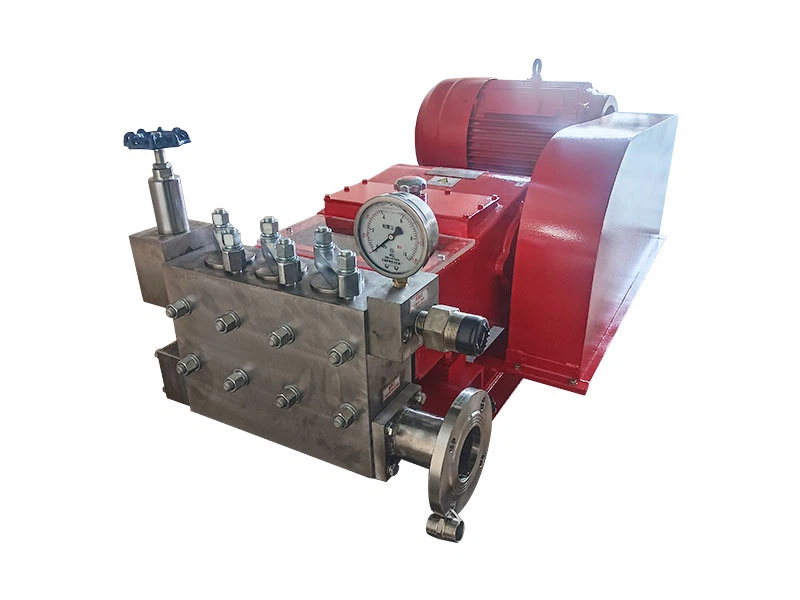

The fire fighter pump is a robust and efficient pump designed specifically for firefighting applications. Engineered to deliver high performance in demanding conditions, this pump ensures reliable water delivery for fire suppression systems, industrial safety, and emergency response. Built with premium materials and advanced design, it is tailored to meet the stringent requirements of fire protection systems.

Product Details

Product Details

· Detailed Parameters:

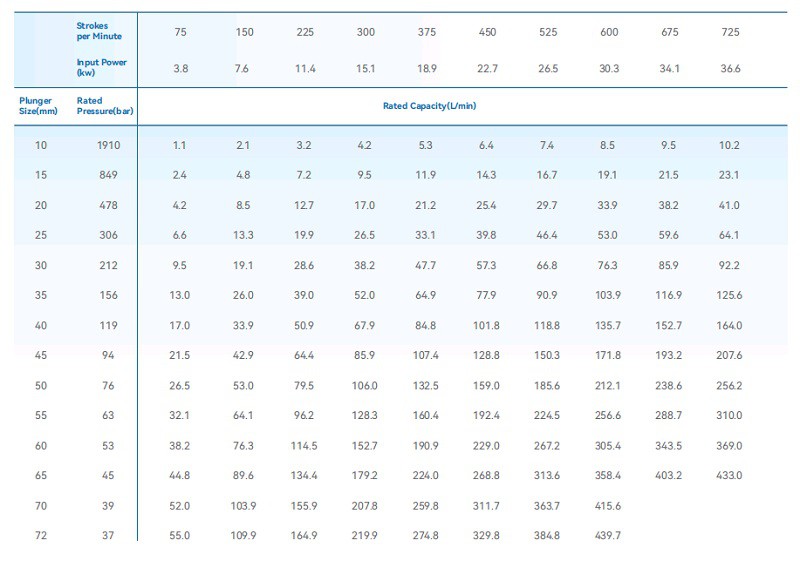

Plunger Diameter: 65mm

Pump Speed: 452rpm

Theoretical Flow Rate: 269.98L/min

Effective Power: 18.97KW

· Drive Power and Method:

Fixed base-mounted design for stability

Belt-driven transmission for smooth operation

Equipped with a standard electric motor

· Medium Contact Material:

Fluid End Cylinder: 304 stainless steel for corrosion resistance

Valve Assembly: 2Cr13 for high durability under pressure

Plunger: 304 stainless steel base coated with Ni60 for wear resistance and extended lifespan

· Additional Features:

Inlet equipped with a buffer ball for pressure stabilization

High-performance filtration system to ensure clean water delivery and protect internal components

Product Parameters

|

3DP60 |

|

|

|

Pump type: 3DP60 |

|

Pressure (bar): 3.5 Mpa |

|

|

Flow rate (L/min): 268 L/min |

|

|

Motor power (KW): 18.5 KW 4-pole |

|

|

Medium: Water |

|

|

Medium temperature ℃: Normal |

|

|

Valve accessories configuration: 1.Vibration-resistant Pressure Gauge 2.Safety Relief Valve |

|

Working Principle

1. Water intake: An external water supply, such as a fire hydrant, pond, river, water tank, etc., supplies water to the pump. Water flows into the pump's water inlet as a result of a pressure differential created by the suction system.

2. Pressurization: Water is forced into the cavity (positive displacement pump) or impeller (centrifugal pump) inside the pump. The water is forced out quickly by the pressure created by the impeller or cavity.

3. Drainage: A hose or permanent system that transports the water to the fire site is connected to the drain valve, which allows the pressured water to exit the pump.

4. Modifying pressure/flow: By adjusting the pump's controls or valves, firefighters can modify the water flow or pressure. The objective is to deliver enough water at the right pressure to the fire scene.

Feature

1. Efficient performance: Fire pumps usually have high-powered engines that can quickly pump and deliver large amounts of water.

2. Portability: Portable fire pumps are designed to be lightweight and easy for firefighters to carry and operate.

3. Durability: Fire pumps are usually made of durable materials and can be used for a long time in harsh environments.

4. Versatility: Fire pumps usually have different water spraying modes and adjustment functions for different types of fires.

Operation steps

1. Preparation: Verify that the fire pump is attached to a dependable water supply and that all of the connection components are sturdy.

2. Start: Turn on the fire pump's engine and modify the pump's output pressure and flow.

3. Water delivery: A hose is used to transport the water supply to the fire area, and firefighters regulate the direction and strength of the water spraying.

4. Monitoring: Keep an eye on the fire pump's functioning to make sure it's operating normally and make necessary adjustments.

Hot Tags: fire fighter pump, China fire fighter pump manufacturers, suppliers, factory