Fire extinguishing pump is a device used to extinguish fires and is usually used in fire protection systems in buildings, factories or other places. This type of pump is usually installed in a building's fire water system to provide high-pressure water flow to extinguish fires. Fire pumps can quickly deliver water to the fire scene to help extinguish the fire and prevent it from spreading. These pumps are typically driven by electric or diesel engines, ensuring rapid response and adequate water pressure in the event of a fire.

Product Details

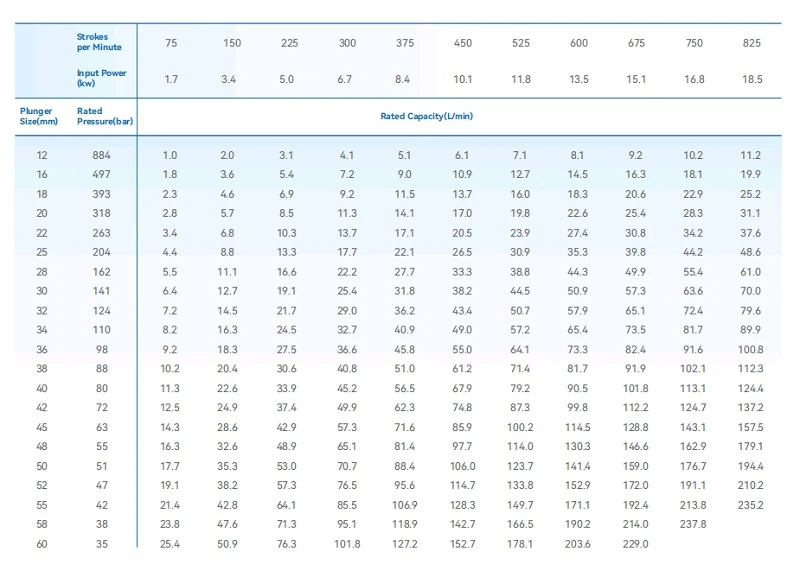

Product Parameters

Please visit our official website to view the complete range of parameters and specifications:https://www.hygyb.com/en/prolist/20

|

3DP40-Case 1 |

|

|

|

Pump Number: 20190739 |

|

Pump Type: 3DP40 |

|

|

Pressure (bar): 32 |

|

|

Flow Rate (L/min): 160 |

|

|

Motor Power (KW): 11 |

|

|

Medium: Water |

|

|

Medium Temperature ℃: Normal Temperature |

|

|

Valve Accessories Configuration: Relief Valve HY-Y15F-00 |

|

|

3DP40-Case 2 |

|

|

|

Pump Number: 20190210 |

|

Pump Type: 3DP40 |

|

|

Pressure (bar): 35 |

|

|

Flow (L/min): 160 |

|

|

Motor Power (KW): 11 |

|

|

Medium: Water |

|

|

Medium Temperature ℃: Normal Temperature |

|

|

Valve Accessory Configuration: Safety Valve HY-Y15F-00 |

|

|

3DP40-Case 3 |

|

|

|

Pump Number: 20170502 |

|

Pump Type: 3DP40 |

|

|

Pressure (bar): 40 |

|

|

Flow (L/min): 70 |

|

|

Motor Power (KW): 7.5 |

|

|

Medium: Clear Water |

|

|

Medium Temperature ℃: Normal Temperature |

|

|

Valve Accessory Configuration: Safety Valve HY-A5-00 |

|

|

3DP40-Case 4 |

|

|

|

Pump Number: 20150719 |

|

Pump Type: 3DP40 |

|

|

Pressure (bar): 100 |

|

|

Flow (L/min): 57 |

|

|

Motor Power (KW): 11 |

|

|

Medium: Clean Water |

|

|

Medium Temperature ℃: Normal Temperature |

|

|

Valve Accessories Configuration: Relief Valve HY-15K-00 |

|

Product composition

1. The engine of the Fire Extinguishing Pump is usually driven by an internal combustion engine or an electric motor.

2. Pump body: The pump body is a part with a propeller that is used to create vacuum and pressure to remove and pressurize the fire extinguisher.

3. Fluid storage container: The Fire Extinguishing Pump is usually equipped with a fluid storage container to hold water or other fire extinguishing materials.

4. Nozzle: The nozzle is the part that sprays the fire extinguishing agent into the fire scene.

5. Control system: The Fire Extinguishing Pump equipment contains a control system that allows you to start and stop the pump, modify the spray pressure, and perform other operations.

Advantage

1. Able to quickly provide large amounts of water or foam to the fire. They are particularly useful in situations where traditional fire hoses cannot reach the affected area, such as high-rise buildings or underground tunnels.

2. Fire pumps come in a variety of sizes and configurations, from small portable units suitable for home use to large industrial systems capable of high pressure and large volumes of water. They can be powered by gasoline engines, diesel engines, or electric motors, and can be configured for use with other fire protection equipment, such as fire sprinkler systems and fire hydrants.

3. Fire extinguishing pumps are also important in preventing fires. Regular inspection and maintenance of fire suppression systems can identify and correct potential hazards before they become hazardous.

Maintenance and Care

1. Regular inspection: Check the various parts of the fire pump, particularly the impeller, bearings, seals, and so on, to ensure proper operation.

2. Cleaning and maintenance: Keep the water intake line, output, and filter clean on a regular basis to avoid pollutants from entering the pump body and causing damage.

3. Check the pump oil: To guarantee that the internal combustion engine runs smoothly, check the oil quantity and quality of the fire pump powered by it.

4. Water pump test: Conduct regular functional tests on the fire pump to confirm that its starting, pressurization, and output capacity are within normal limits.

5. Winter maintenance: If the fire pump is operated in cold weather, special attention should be made to antifreeze to keep the water pump and pipes from freezing due to the low temperatures.

Selection of Fire Extinguishing Pump

1. Flow and pressure requirements: Choose an appropriate fire pump based on your unique fire extinguishing demands.

2. Pump drive mode: Depending on whether electricity is available on-site, choose between an electric fire pump and an internal combustion engine-powered fire pump.

3. Working environment: Select a fire pump that can adapt to a variety of working conditions (e.g., high temperature, cold, high altitude).

4. Portability: A mobile fire pump's weight and volume must be evaluated to ensure that it is convenient to transport and use.

Quality Testing Equipment

Hot Tags: fire extinguishing pump, China fire extinguishing pump manufacturers, suppliers, factory