The Hydro Jet Cleaning Pump is an efficient cleaning device commonly used to clean pipes, drainage systems, sewage treatment facilities and other places that require powerful water flow for cleaning. This type of pump usually consists of a powerful water pump and a nozzle that produces a high-pressure flow of water to remove dirt, sediment and blockages.

Product details

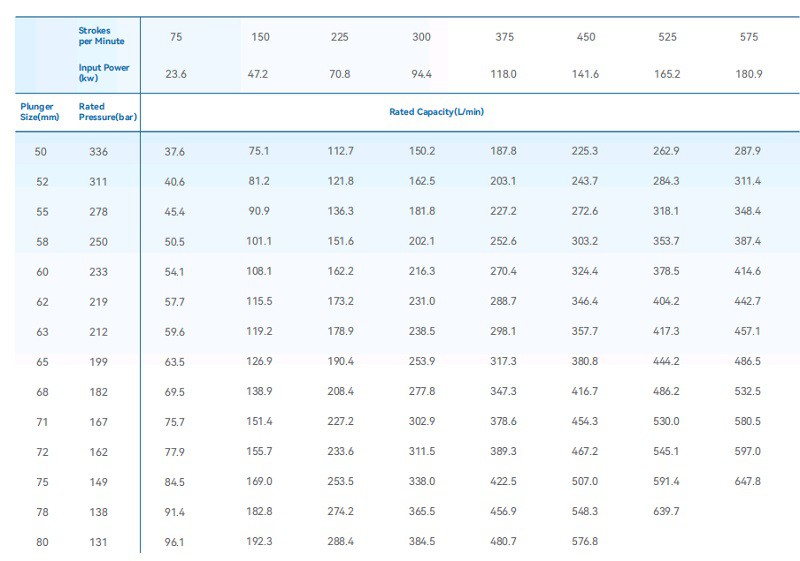

Product Parameters

Please visit our official website to view the complete range of parameters and specifications:https://www.hygyb.com/en/prolist/20

|

3ZW85-Case 1 |

|

|

|

Pump number: 20210907 |

|

Pump type: 3ZW85 |

|

|

Pressure (bar): 180 |

|

|

Flow rate (L/min): 300.6 |

|

|

Motor power (KW): 110 |

|

|

Medium: water |

|

|

Medium temperature ℃: normal temperature |

|

|

Valve accessories configuration: 1. Safety valve A22Y-250C DN25 |

|

|

3ZW85-Case 2 |

|

|

|

Pump number: 20170333 |

|

Pump type: 3ZW85 |

|

|

Pressure (bar): 320 |

|

|

Flow rate (L/min): 200.4 |

|

|

Motor power (KW): 132 |

|

|

Medium: clean water |

|

|

Medium temperature ℃: normal temperature |

|

|

Valve accessories configuration: 1. Overflow valve HY-Y38K-00 2. Safety valve A22Y-400 DN15 3. Accumulator NXQ1-L4/31.5 4. TH-1 filter 200 mesh 304 2" 5. Pipeline pump ISW65 -160 |

|

Advantage

1. Efficient cleaning: High-pressure water flow is able to quickly remove stubborn dirt and blockages.

2. No chemical pollution: No chemical cleaning agents are used, reducing environmental pollution.

3. Wide range of applications: Suitable for surfaces of a variety of materials and shapes.

4. Cost saving: Reduce cleaning time and labor costs.

5. Safe and reliable: Easy to operate and convenient to maintain.

How it works

Water inlet: Filter removes impurities and protects the pump.

Pressing: Plunger increases water pressure to 10,000–40,000+ PSI.

Jet: Pressurized water is ejected through a tiny nozzle hole (0.5–2 mm) to create a supersonic water stream.

Impact: The kinetic energy of the jet attacks coatings, rust, or deposits without damaging the substrate.

Application

1. High-pressure jet cleaning pumps are commonly used in pipeline cleaning for oil, gas, chemical, and power industries.

2. Regular cleaning of industrial equipment (e.g. heat exchangers, boilers, reactors, cooling towers) is necessary to ensure efficient operation.

3. High-pressure jet cleaning pumps are often used to remove dirt, mildew, and pollutants off building faces, including walls, floors, and roofs.

4. Car and ship cleaning: High-pressure jet cleaning pumps effectively remove dirt, grease, and contaminants from vehicle surfaces.

5. Industrial cleaning involves cleaning machinery and equipment, factory floors, and mechanical parts to preserve hygiene in industries including mechanical processing and food processing.

Maintenance and precautions

Regular inspection and maintenance:

Inspect the pump body, pipes, nozzles, and other parts for wear on a regular basis.

Check the filter and water source to ensure that the water is pure and that contaminants do not clog the pipes or nozzles.

To avoid excessive wear, keep the pump body's moving parts lubricated on a regular basis.

Water source problem:

The quality of the water source for the Hydro Jet Cleaning Pump is extremely crucial. Water that is overly hard or includes a high concentration of pollutants might clog the pump body, pipelines, and nozzles, reducing cleaning efficiency and equipment life.

Avoid excessive pressure:

During use, avoid increasing the pressure too much, especially while cleaning more fragile equipment or surfaces. Excessive pressure may result in surface or equipment damage.

Safe operation:

The pressure produced by the Hydro Jet Cleaning Pump is exceptionally high. To avoid injury, use it with extreme caution and stay away from high-pressure water. In addition, the operator should wear proper protection equipment, such as safety glasses, gloves, and outerwear.

Quality Testing Equipment

Hot Tags: hydro jet cleaning pump, China hydro jet cleaning pump manufacturers, suppliers, factory