Inlet and outlet valve kits are fundamental to the operation of high-pressure plunger pumps, regulating the flow of fluid into and out of the pump chamber to ensure efficient and reliable performance. A valve is usually composed of the following smaller parts:

Valve Seats: These are the surfaces against which the valves seal when closed, ensuring a tight seal to prevent leakage.

Valve Discs or Balls: These are the movable components of the valves that open and close to control the flow of fluid.

Valve Springs: These springs provide the force necessary to keep the valve discs or balls seated against the valve seats when closed, ensuring a tight seal.

Valve Retainers: These components hold the valve discs or balls in place and help guide their movement to ensure proper operation.

Valve Guides: These guides help stabilize the movement of the valve discs or balls, ensuring smooth operation and preventing binding or sticking.

Products Description

The inlet valve kit typically includes one or more inlet valves that allow fluid to enter the pump chamber during the suction stroke. These valves are designed to open and close at precise intervals to control the flow of fluid into the pump.

The outlet valve kit consists of discharge valves that permit fluid to exit the pump chamber during the discharge stroke. These valves are engineered to prevent backflow and ensure that fluid is expelled from the pump chamber with minimal resistance.

Both inlet and outlet valve kits are constructed from durable materials such as stainless steel or hardened alloys to withstand the high pressures and repetitive cycling encountered in high-pressure pump applications. They are precision-engineered to provide tight sealing and reliable operation over extended periods of use.

Product Parameters

Material: UNS S20910

Mechanical Performance:

σb≥621 MPa

σs≥345 MPa

δ5≥35%

ψ≥55%

HRC≤22

feature

Directional Control: The inlet and outlet valve kits regulate the direction of fluid flow within the pump, ensuring that fluid moves through the pump in the desired direction during each phase of the pumping cycle.

Timing Control: The opening and closing of the inlet and outlet valves are synchronized with the movement of the plungers or pistons, controlling the timing of fluid intake, compression, and discharge to maintain efficient pump operation.

Leakage Prevention: Tight sealing of the inlet and outlet valves prevents fluid from leaking back into the pump chamber during the discharge stroke, maximizing pump efficiency and preventing loss of pressure.

Flow Regulation: By opening and closing the inlet and outlet valves at specific times, operators can control the volume and pressure of fluid output, allowing for precise regulation of flow rates to meet the requirements of various industrial applications.

Processing Equipment

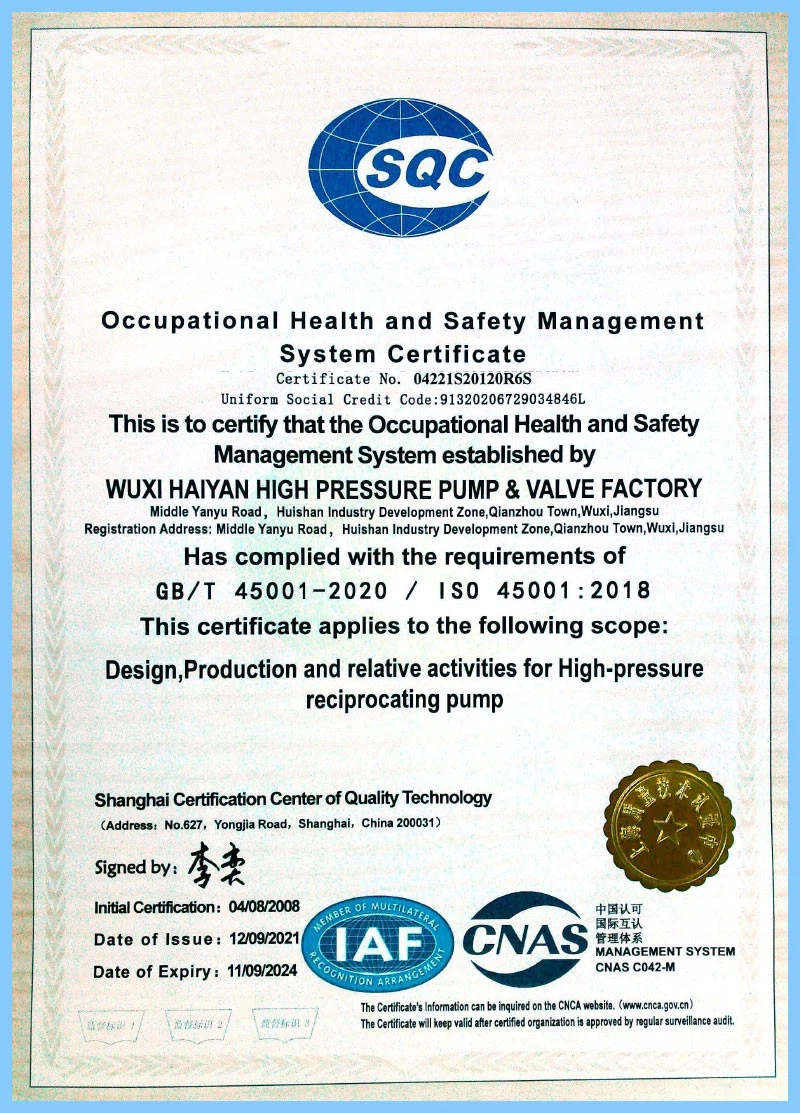

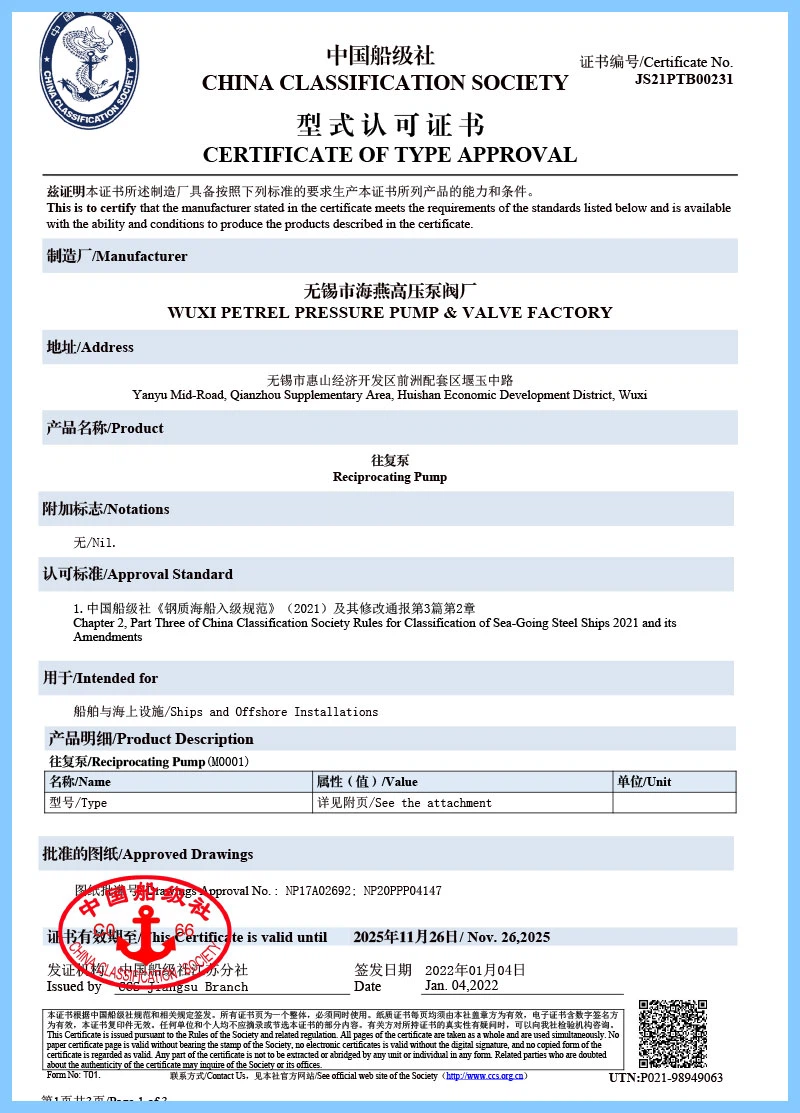

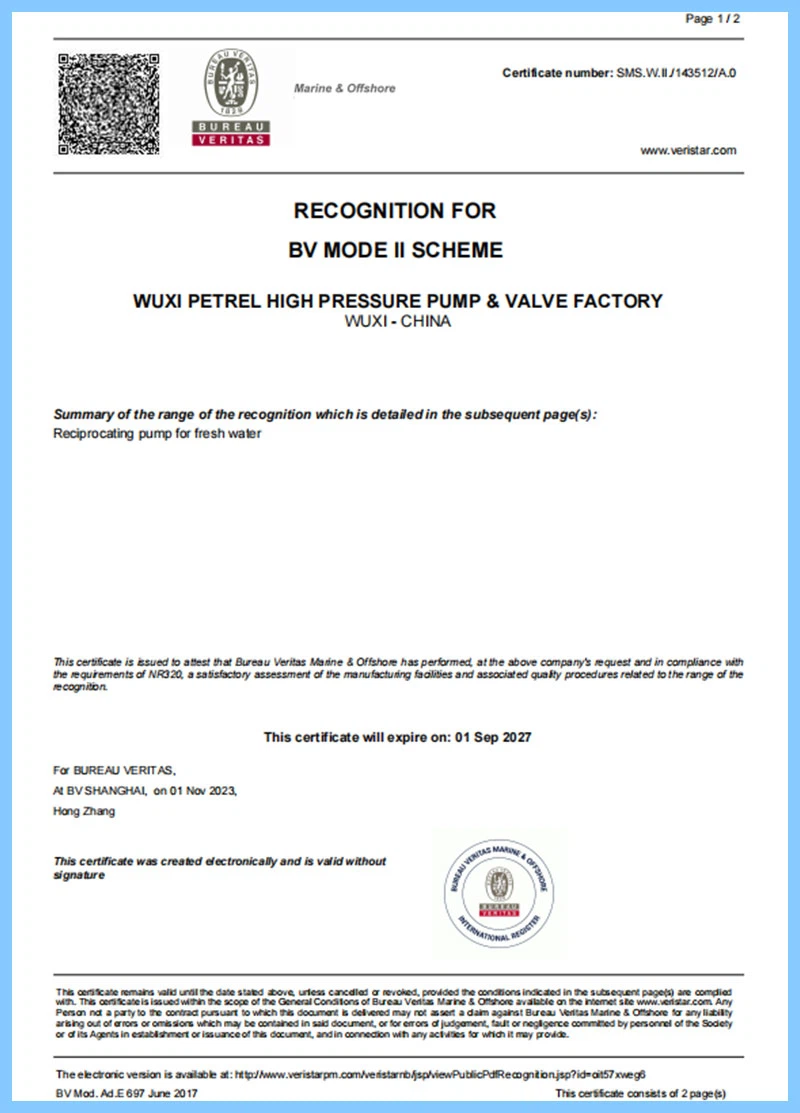

certificate

Hot Tags: valve kits, China valve kits manufacturers, suppliers, factory